SMART REACTORS

Global medial device coating company providing hemocompatible surface coatings for implantable and interventional devices

Hemocompatible Medical Device Coatings | Smart Reactors

Our hemocompatible implant coating technology is designed for blood-contacting medical devices, including neurovascular and cardiovascular implants, surgical implants, ECMO and blood filters, orthopedic, cosmetic and dental implants where controlled healing, reduced thrombosis and an anti-inflammatory response are critical to implant technology.

TECHNOLOGY

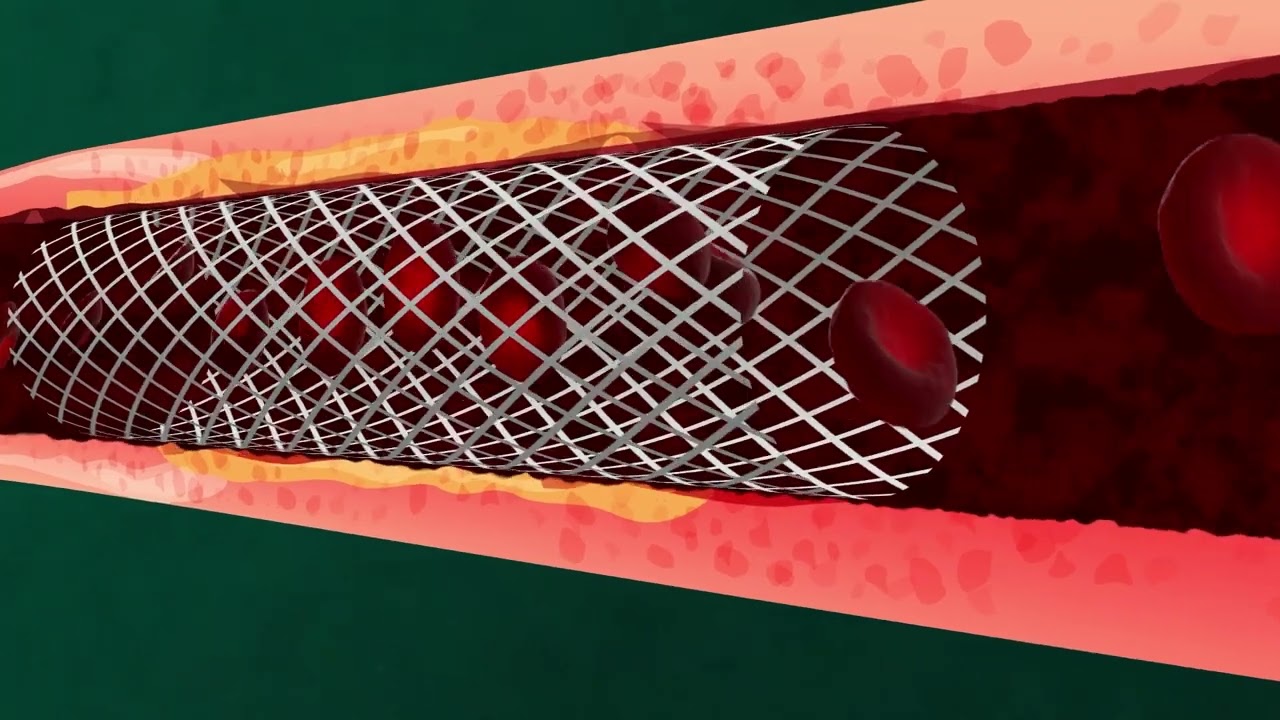

Camouflage™ is a high performance medical device coating technology with long-term stability, durability & enhanced healing on blood contacting devices. The problems we solve include;

Thromoembolic Complications

In the world of medical implants, hemocompatibility is not just a requirement—it’s a necessity. Devices that come into contact with blood must function seamlessly, without triggering complications like clotting, inflammation, or immune responses.

Read More

Vessel Endothialization

The integration of surface coatings, such as Camouflage™, aims to mitigate these complications by enhancing both hemocompatibility and endothelialization, allowing for smoother recovery and better device integration.

Read More

Anti-Microbial Growth

In medical device manufacturing, preventing infection is as critical as enhancing functionality. Devices that interact with the body, especially in sensitive areas like surgical implants or blood-contacting surfaces, are at constant risk of bacterial colonization, which can lead to severe infections. Read More

CAPABILITIES

Camouflage™

Key Features Includes:

Excellent Hemocompatibility

Minimizes Thrombus Promotion.

Accelerated Endothelialization

Reduces Thromboembolic Conditions.

Drug-Free Solution

Shortened Regulatory Pathway.

Antimicrobial Properties

Reduction In Biofilm Formation.

Choose Camouflage™

Our R&D team are avaliable to discuss your projects needs to provide real solutions.

PROJECT

CellMembrane

Cellmembrane is an innovative nanocellulose-based technology designed to revolutionize artificial lung devices. This breakthrough could serve as a vital bridge for lung transplant patients, offering a global solution for individuals in need of respiratory support.

Services

Prototype coating

Enhance device performance with our advanced biocompatible coating. Coating tailored to meet your needs from concept to clinic.

Design & Development

Streamline your device development with our expert design and process optimization services, ensuring efficiency and manufacturability at every stage.

Manufacturing transfer

Seamlessly transition from development to full-scale production with our expert technical transfer and manufacturing support services.

After sales support

Ensure the long-term success of your medical devices with our comprehensive after-sales support, including maintenance, upgrades, and compliance assistance.

Who We Are

Smart Reactors is a trusted provider of medical device coating technologies to the medical device landscape. We differ to the competition by providing a real coating solution to reduce Thromboembolic Complications, while promoting Cell Proliferation & Healing in the case of implant devices (ie-neurovascular, flow diverters, venous stents, structural heath devices etc).

We offers a wide range of services, ranging from early coating selection to manufacturing process transfer and support with regulatory approval & commercialisation.

The company’s business model is to partner with manufactureres & solve clinical challenges when devices substrates are subject to blood circulation over the medium to longer term. Our technology is commercialized through license and royalty agreements. The company produces and distributes surface coatings to the diagnostic and biomedical research markets. Smart Reactors is headquartered Ireland.