Camouflage™ Technology

Camouflage™ Technology

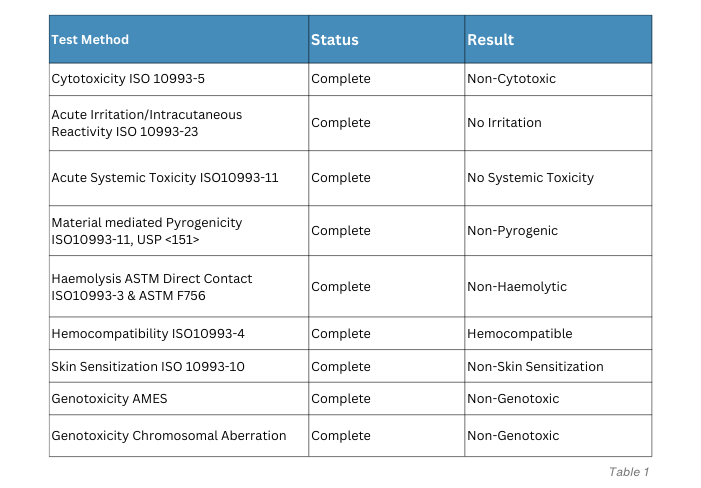

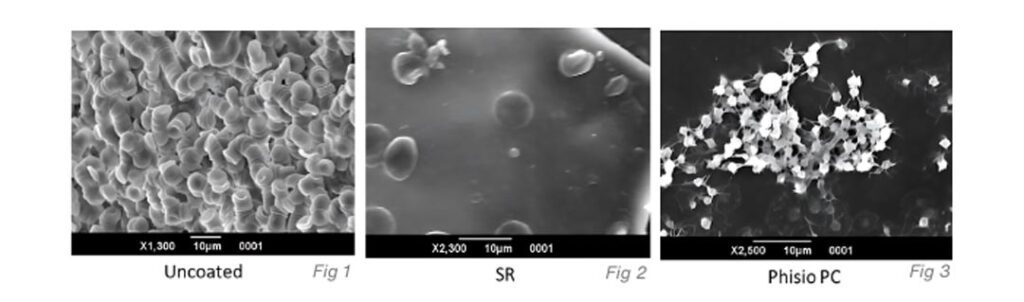

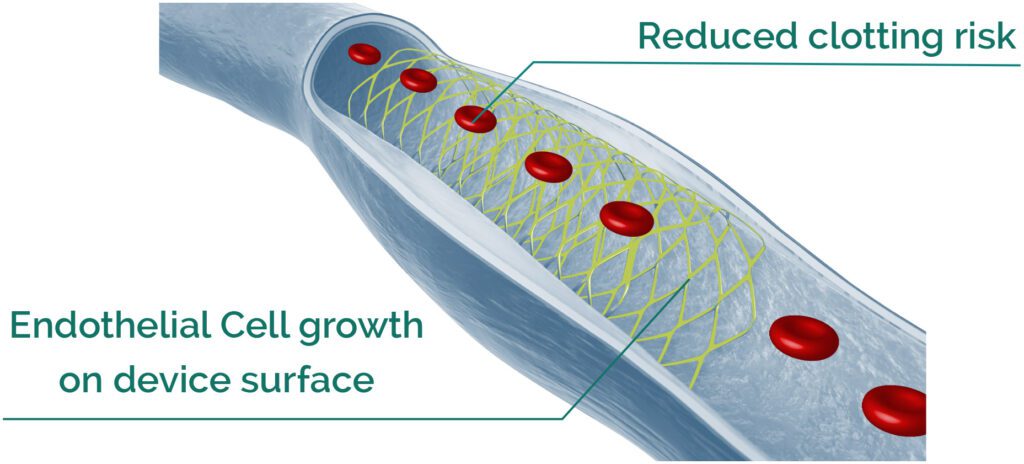

Camouflage™ technology is a proprietary coating technology incorporating a synthetic polymer combined with a proteinaceous base layer. The coating technology is non-toxic, demonstrates excellent hemocompatibility and endothelialization. It is designed to reduce clotting cascade initiation and provides long-term stability for use on a range of blood-contacting medical devices. Camouflage™ is underpinned by solid Intellectual property (IP) to differentiate and create value for our customers.

Camouflage™ is a passive (non-heparin) biocompatible coating which utilizes a gentle water-based chemistry. It adheres to all medical grade material without the need for UV or thermal crosslinking. By design, the “mechanism of action” provides for a cloaking effect on the device surface to mask from the circulating blood. Camouflage™ is your only choice for a smooth pathway to regulatory approval.

Camouflage™ is a high performance biocompatible coating technology with long-term stability & durability performance on blood contacting devices. The problems we solve include;

Thromoembolic Complications

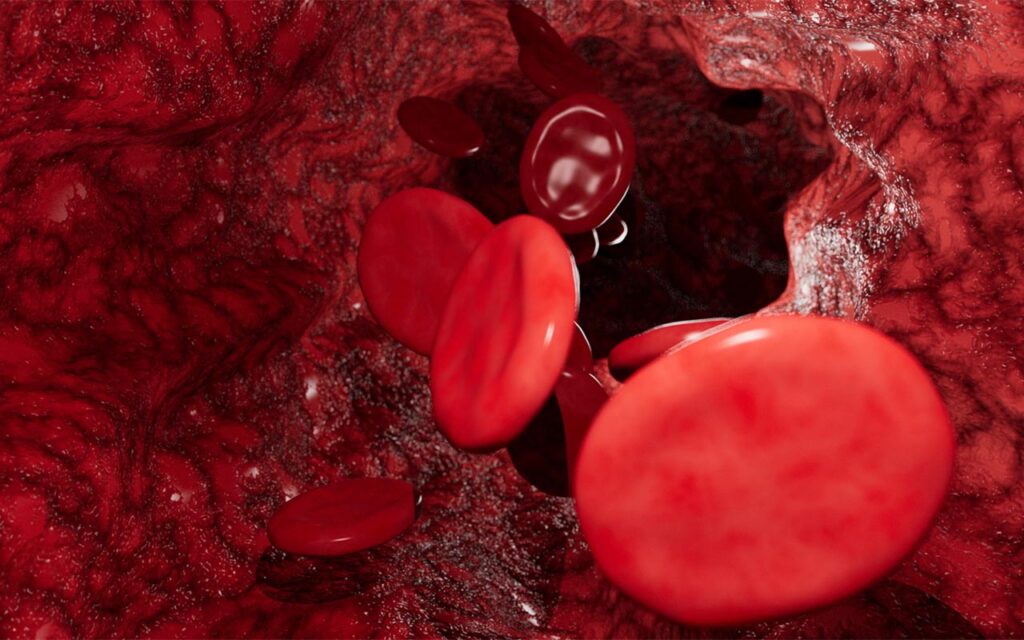

In the world of medical implants, hemocompatibility is not just a requirement—it’s a necessity. Devices that come into contact with blood must function seamlessly, without triggering complications like clotting, inflammation, or immune responses.

Read More

Vessel Endothelialization

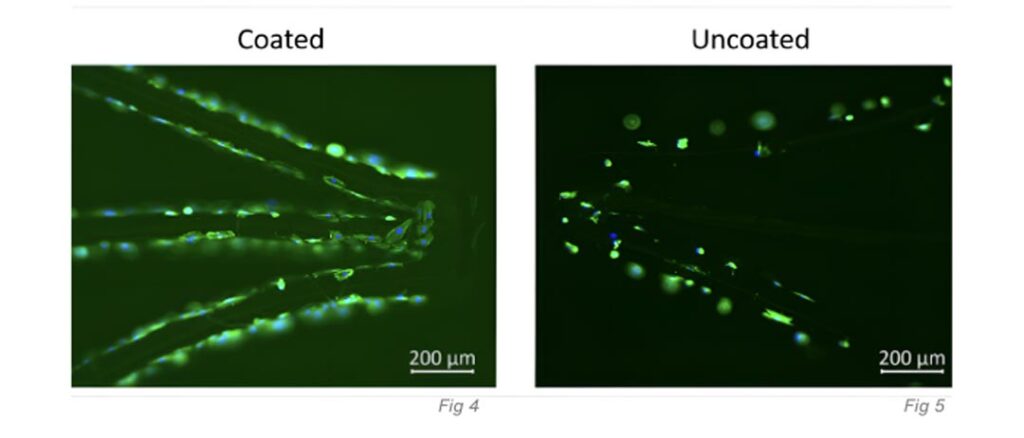

The integration of surface coatings, such as Camouflage™, aims to mitigate these complications by enhancing both hemocompatibility and endothelialization, allowing for smoother recovery and better device integration.

Read More

Anti-Microbial Growth

In medical device manufacturing, preventing infection is as critical as enhancing functionality. Devices that interact with the body, especially in sensitive areas like surgical implants or blood-contacting surfaces, are at constant risk of bacterial colonization, which can lead to severe infections.

Read More

Mechanism of Action

Camouflage™ acts by retaining a layer of the patient’s non-inflammatory proteins (red blood cells and blood components) on the coating. This hemocompatible coating masks the device surface from the circulating blood, reducing the body’s reaction to the foreign material. It also promotes endothelization, supporting the attachment of endothelial cells for long-term biocompatibility. Additionally, the antimicrobial properties of the coating help prevent infection, ensuring a safer and more durable implant.

Benefits of Camouflage™

Excellent Performance

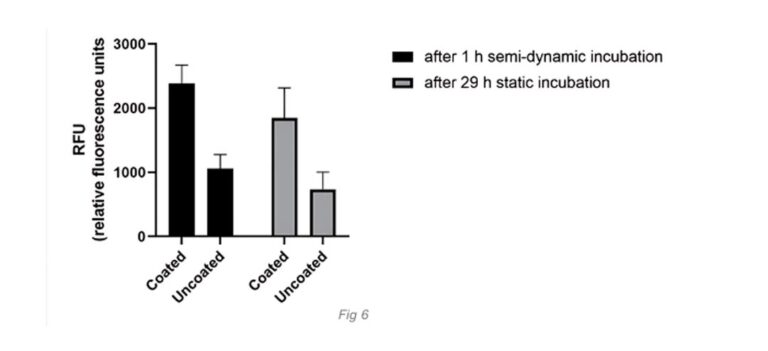

Camouflage™ coating technology demonstrates superior hemocompatibility and promotes endothelialization.

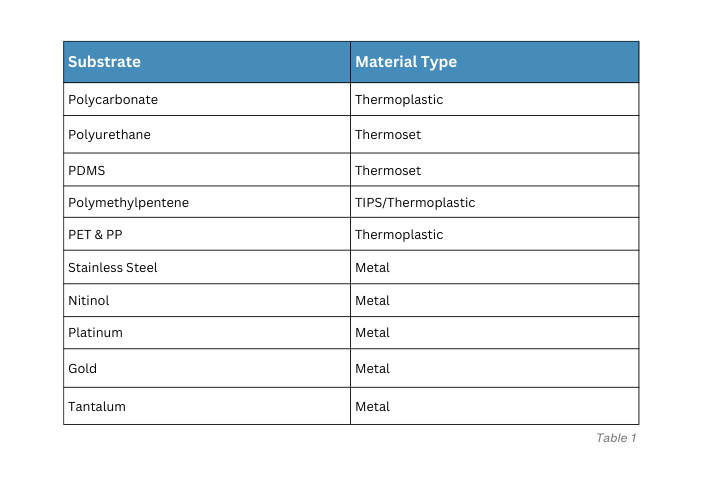

Adheres to many Substrates

Camouflage™ coating is a versatile coating that adheres to many substrates.

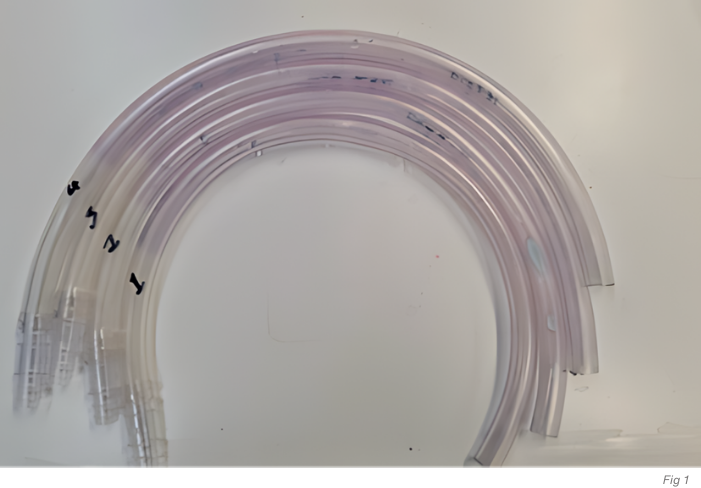

Ultra-Thin Coating

Camouflage™ coating is a superior thin coating, colourless to the naked eye.

Long Term Durability

Camouflage™ coating demonstrates longer term durability on a range of devices.

Non-Medicinal and Heparin Free

Camouflage™ coating technology is a non-medicinal solution.

Lean Manufacturing Process

Camouflage™ coating technology is easy to integrate into manufacturing process.

Choose Superior Coating.

Choose Camouflage™ Today.

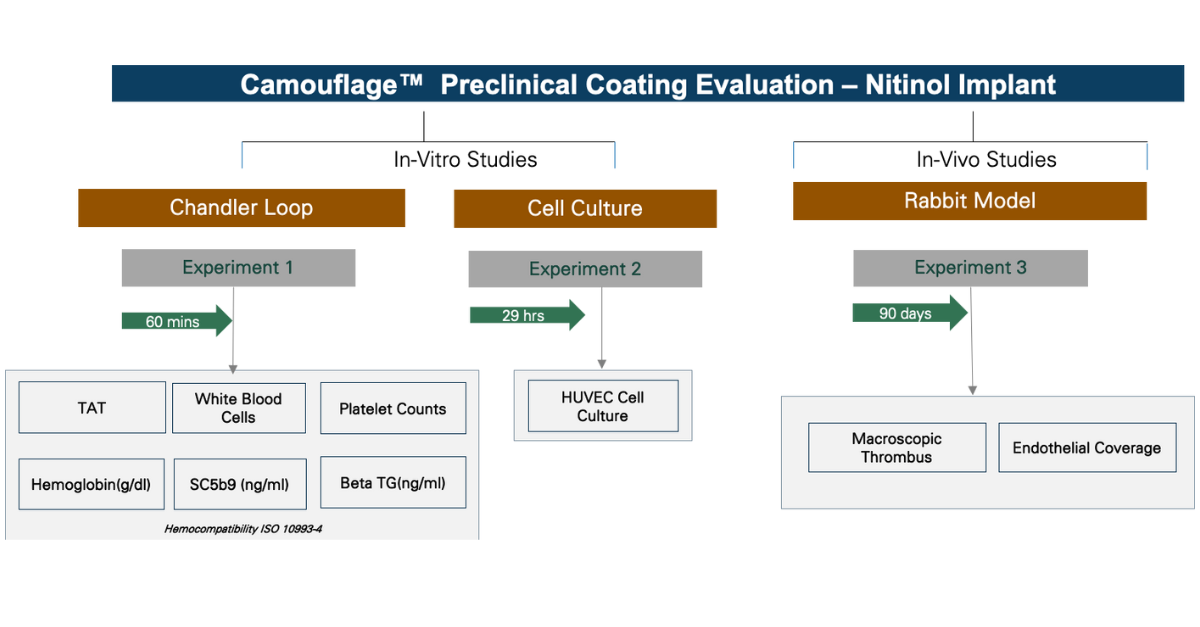

Preclinical Evaluation of Camouflage™ Coated Stents in a Rabbit Carotid Model