Cell Membrane

CellMembrane

CellMembrane is a novel nanocellulose technology for Next Generation artificial lung devices. Smart Reactors in collaboration with top universities is working to develop this technology to help lung patients.

The Problem

Lung disease is the third most common cause of death worldwide, with patients often suffering from shortness of breath impeding their day-to-day life. This is caused by the insufficient transfer of oxygen and carbon dioxide in the blood due to reduced lung functionality. Currently the only long-term form of treatment for these diseases is lung transplantation which has its own issues including long wait times for a donor. This highlights the need for an artificial lung device which can bridge the gap for patients waiting for lung transplants.

Current state of the art Technology

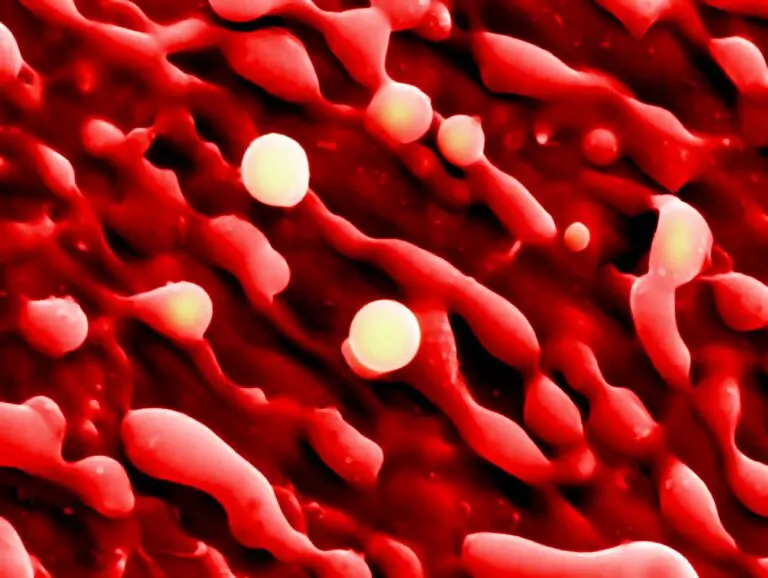

Current artificial lung technology includes extracorporeal membrane oxygenation, or ECMO. During this process blood is taken from a patient’s vascular system and circulated, via a mechanical pump, outside the body to allow for the exchange of carbon dioxide and oxygen in the blood. Although these devices have gone through decades of research and innovation, they still have their shortcomings associated with the internal gas exchange membrane of the device. Current devices don’t allow for the correct blood flow seen within the lung which can lead to the formation of blood clots. This can cause blockages within the device reducing the membrane’s ability for gas transfer.

Nanocellulose as The Solution

With all the issues associated with current ECMO devices and the internal gas exchange membrane, further research into the design of artificial lung devices which mimic the gas transfer as well as the blood flow seen within the lung is needed. After receiving funding from the European Innovation Council, Smart Reactors are currently in the process of developing a novel “nanocellulose” membrane which is sustainable, affordable, has a high level of biocompatibility and most importantly mimics the processes seen within the human lung. The use of this material would reduce the risk of blood clots and would allow for long term use of the device bridging the gap for patients to lung transplantation.

Using Sustainable Materials

This innovation is based on the principles of biomimicry which applies the fields of engineering, chemistry, and biology to materials as well as systems or machines that have functions that copy biological processes. We at Smart Reactors believe that nanocellulose will be a promising avenue for the improvement of the efficiency of the gas transfer, safety, and long-term use of ECMO devices to better suit current clinical needs. Sustainability is also key to how Smart Reactors approach our business and the use of nanocellulose from biological materials and avoiding the use of petrochemicals will lead to a more sustainable future. The development of a biomimetic organ from nanocellulose material is an example of how we are leading by example and using sustainable materials in our designs.