Vascular grafts are critical devices used to bypass or replace diseased blood vessels, restoring blood flow in patients with cardiovascular and peripheral vascular diseases. Despite decades of clinical use, synthetic and biological grafts face persistent challenges, including thrombosis, infection, and failure to maintain long-term patency. Ongoing innovations in surface engineering — such as Smart Reactors’ Camouflage™ coating — are helping address these limitations by improving hemocompatibility and graft performance.

The Persistent Challenge of Thrombosis

One of the primary limitations of synthetic vascular grafts, especially in small-diameter applications, is early thrombotic occlusion. Without a living endothelial layer, synthetic surfaces present a thrombogenic interface that activates platelets and initiates clot formation. Studies show that small-diameter (<6 mm) synthetic grafts have significantly lower patency rates compared to autologous vein grafts, primarily due to thrombotic complications.

Biological grafts, such as autologous saphenous veins, naturally resist thrombosis thanks to their intact endothelial lining. However, not all patients have suitable veins for harvest, and repeated procedures may exhaust available conduits.

Infection Risk and Biofilm Formation

Infection remains another serious complication associated with synthetic grafts. Polymers like ePTFE and Dacron can serve as substrates for bacterial adhesion and biofilm development. Once infected, synthetic grafts are difficult to salvage and often require complete removal. This risk is particularly significant in dialysis access grafts, where repeated needle punctures increase the risk of contamination.

Biological grafts demonstrate lower infection rates but can still fail if infected. Preventing microbial colonization and enhancing graft integration are central to improving patient safety.

Mechanical Mismatch and Intimal Hyperplasia

Another major challenge is the mismatch between graft mechanical properties and native vessel dynamics. Synthetic grafts can exhibit compliance differences that alter flow patterns at the anastomosis site. This mechanical mismatch often leads to disturbed flow, which contributes to intimal hyperplasia — the abnormal growth of tissue inside the vessel that can narrow the lumen and cause graft failure.

Achieving compliance similar to native arteries while maintaining structural durability remains a key design goal for next-generation grafts.

Long-Term Patency: The Ultimate Goal

Long-term patency — the ability of a graft to remain open and functional over time — is the ultimate measure of graft success. Large-diameter synthetic grafts generally perform well in high-flow settings such as the aorta. However, for peripheral and coronary bypasses, patency rates decrease as vessel diameter decreases.

The gold standard for small-diameter bypasses remains the autologous vein. Still, the field continues to pursue synthetic and bioengineered solutions that can match or exceed the performance of biological conduits while offering scalable manufacturing.

Surface Modification: A Critical Solution

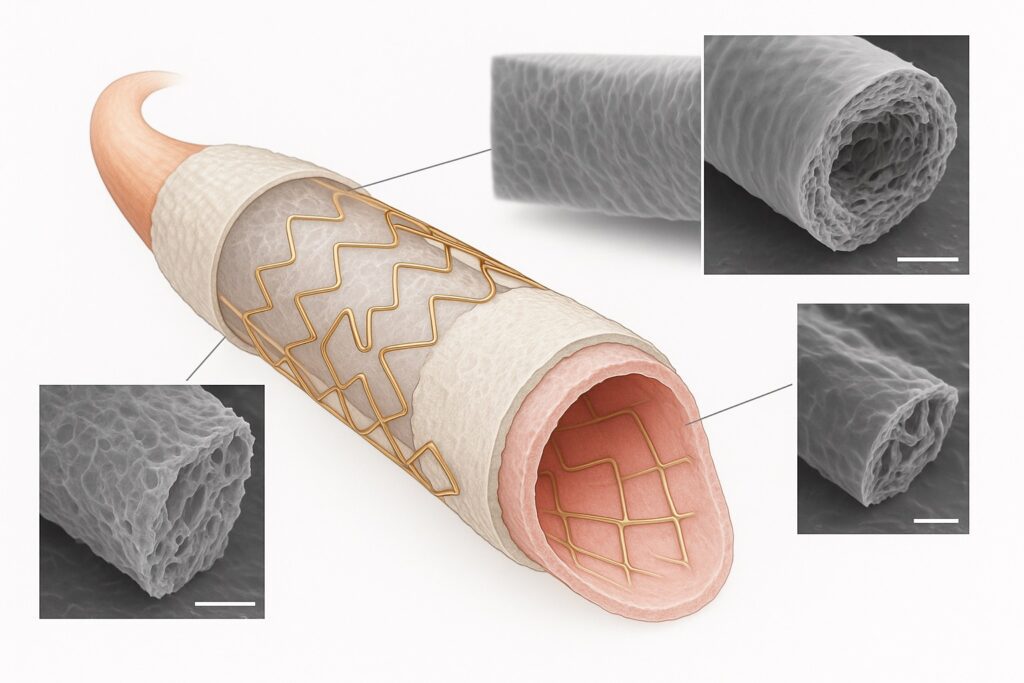

To overcome thrombogenicity and poor endothelialization, surface engineering plays an essential role. Hemocompatible coatings reduce platelet adhesion, dampen clot formation, and create conditions that support natural healing.

Smart Reactors’ Camouflage™ coating is an advanced surface technology designed to improve the hemocompatibility of synthetic vascular grafts. By creating a bioinspired, non-thrombogenic surface, Camouflage™ helps minimize early clot formation and supports smoother blood interaction. This makes it possible to extend the performance of synthetic grafts into small-diameter applications, where thrombosis risk has historically limited their use.

Future Directions: Towards Biofunctional Grafts

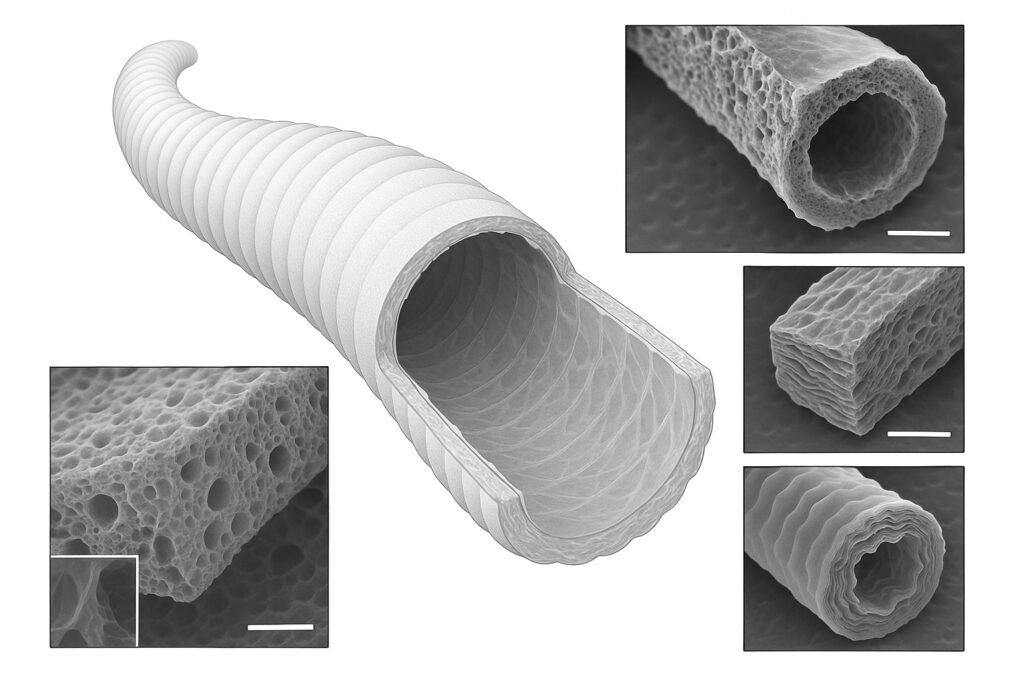

Beyond coatings, researchers are developing tissue-engineered vascular grafts (TEVGs) that combine biodegradable scaffolds with patient-derived cells. The goal is to replicate the natural structure and function of native vessels, promoting complete integration and remodeling over time.

While promising, TEVGs face challenges in large-scale production, cost, and regulatory approval. Until such solutions become widely available, improving existing synthetic grafts with advanced coatings remains one of the most practical approaches to enhance outcomes.

Key Takeaway

Thrombosis, infection, mechanical mismatch, and poor long-term patency remain core challenges in vascular graft technology. Addressing these issues requires a combination of improved materials, surface modifications, and bioengineering.

Camouflage™ coating is a practical, advanced solution that enhances the hemocompatibility of synthetic grafts, supporting safer, more durable performance in vascular repair and bypass procedures.

Learn how Smart Reactors’ Camouflage™ technology can help your vascular graft designs achieve better hemocompatibility and long-term success. Contact us to discuss integration and technical support.

Share this post: on LinkedIn