What Is ECMO and Why Hemocompatibility Matters

Extracorporeal Membrane Oxygenation (ECMO) is a life-sustaining system used in critical care for patients with severe heart or lung failure. It works by circulating and oxygenating the patient’s blood outside the body, giving the organs time to rest and heal.

Perfusion—the circulation of oxygen-rich blood to vital tissues—is an essential component of ECMO. A perfusionist oversees the circuit, ensuring optimal flow, oxygenation, and temperature regulation. However, the materials in ECMO systems often contact blood directly, and if they are not hemocompatible, they can trigger serious complications like clot formation or inflammation.

Real-World Use Cases for ECMO in Critical Care

ECMO is often employed as a final line of support when conventional treatments, such as mechanical ventilation or pharmacological interventions, are no longer effective. Its adaptability makes it suitable for several high-risk clinical situations:

Acute Respiratory Distress Syndrome (ARDS)

In ARDS, the lungs become severely inflamed and fluid-filled, impairing oxygen exchange. ECMO allows clinicians to rest the lungs while maintaining systemic oxygenation, reducing ventilator-induced lung injury and improving survival chances.

Severe COVID-19

During the COVID-19 pandemic, ECMO was used in intensive care settings for patients with profound respiratory failure unresponsive to mechanical ventilation. Prolonged extracorporeal support gave patients time to recover from the viral injury while maintaining oxygen delivery to critical organs.

Cardiogenic Shock and Cardiac Arrest

In cases of acute cardiac failure, such as myocardial infarction or myocarditis, veno-arterial (VA) ECMO provides circulatory and respiratory support. It serves as a bridge to recovery, surgical intervention, or transplantation in cases where cardiac output is severely compromised.

Neonatal and Pediatric Support

ECMO is also widely used in neonatal and pediatric care for conditions like congenital diaphragmatic hernia, persistent pulmonary hypertension, or postoperative cardiac complications. Pediatric circuits are designed for lower flow rates and reduced blood volumes.

Bridge to Transplant or Long-term Support

For patients awaiting heart or lung transplants, ECMO can be used as a bridge-to-transplant solution. It provides stability during the wait period and can be combined with other support modalities such as ventricular assist devices (VADs).

How ECMO and Perfusion Systems Work

An ECMO setup includes:

Cannulas and Tubing: Direct blood in and out of the patient.

Blood Pump: Propels blood through the circuit (centrifugal or roller types).

Membrane Oxygenator: Performs gas exchange, acting like an artificial lung.

Heat Exchanger: Regulates blood temperature before it returns to the body.

Monitors and Filters: Measure pressure and remove air/debris.An ECMO and perfusion circuit comprises several key components that facilitate extracorporeal support and adequate blood flow. These include cannulas, tubing, blood pumps, membrane oxygenators, heat exchangers, pressure monitors, and filters.

Common Materials used in ECMO and Perfusion

There is a wide range of materials used in the construction of an ECMO circuit. The majority of components are fabricated using polymers which include polyvinyl chloride (PVC), polyurethane, silicone, and polyethylene. These polymers are used due to their inherent flexibility, and high level of biocompatibility and they also have the ability to withstand blood flow without material degradation or harmful effects to the blood.

| Component | Material | Benefit | Risk Without Coating |

| Tubing | PVC, Polyurethane | Flexible, Biocompatible | May trigger platelet adhesion |

| Oxygenator Membrane | PMP or Polypropylene | Gas exchange efficiency | Plasma leakage or clotting |

| Heat Exchanger | Stainless Steel | Heat conductivity, corrosion resistance | Thrombogenic surface |

Why Hemocompatible Coatings Are Critical

Without hemocompatible coatings, ECMO circuits may activate the clotting cascade, increasing the risk of thrombus formation. This not only threatens patient safety but can impair device function.

What coatings must achieve:

- Avoid affecting gas exchange efficiency

- Inhibit clot initiation under dynamic blood flow

- Remain durable under continuous perfusion

Camouflage™: A Proven Coating for ECMO Systems

Smart Reactors’ proprietary Camouflage™ coating is designed to enhance hemocompatibility without compromising gas exchange.

✅ Ultra-thin and biocompatible

✅ Applies uniformly to tubing, pumps, and oxygenators

✅ Maintains open channels between hollow fibers for uninterrupted oxygen and CO₂ transfer

✅ Tested under flow conditions with consistent performance

This coating helps minimize clotting and supports longer ECMO runs without device fouling or degradation.

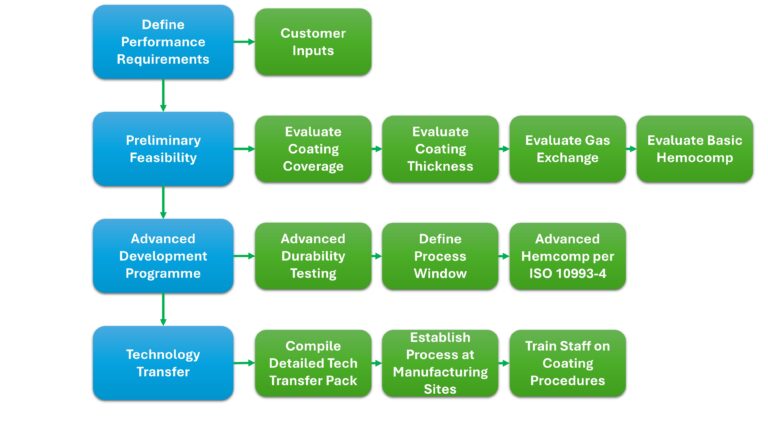

How to Evaluate a New Coating for ECMO and Perfusion Equipment

When deciding on a new hemocompatible coating for your device it is important to know the appropriate steps required to evaluate that coating and determine its suitability. The Figure below illustrates a summary of the process to be undertaken for qualifying Smart Reactors CamouflageTM coating on ECMO and Perfusion equipment.

The Future: Nanocellulose Membranes and the CellMembrane Project

Smart Reactors, in partnership with leading EU universities, is pioneering nanocellulose-based oxygenator membranes through the CellMembrane project. These next-generation membranes aim to:

- Mimic natural lung tissue

- Improve sustainability and cost-effectiveness

- Enhance gas exchange and hemocompatibility

- Extend device longevity for transplant bridging

🔗 Follow CellMembrane on LinkedIn for project updates.

Conclusion: Safer Circuits, Better Outcomes

ECMO is a remarkable technology—but its success depends on the fine details of circuit design and surface chemistry. Hemocompatible coatings are essential for reducing clotting risks, improving patient outcomes, and enabling safer long-term use.

With Smart Reactors’ Camouflage™ coating, medical teams can count on consistent performance, validated safety, and uncompromised gas exchange even in high-stakes scenarios.

Share this post: on LinkedIn